Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Discover essential insights on mitigating supply chain risks for export managers in the agri industry. Learn how proactive strategies and innovative solutions can safeguard operations and unlock new growth opportunities.

The food export industry is more complex than ever before. As global markets grow, the traceability challenges in food export grow at every step of the supply chain. On top of that, regulations are tightening, and consumers are demanding more transparency than ever. Whether you’re exporting fresh produce, processed food, or packaged goods, the need for clear, reliable traceability has never been so important.

Many food exporters face significant hurdles when it comes to maintaining end-to-end traceability. Without a solid traceability system in place, businesses run the risk of non-compliance with international regulations, which can result in costly fines, delays, or even product recalls. Additionally, the absence of transparency can erode consumer trust, which is more valuable than ever in today’s competitive market. Blockchain offers a transparent, secure, and real-time way to track products through every stage of the supply chain.

Key Takeaways

From 2000 to 2021, global food trade surged by 350%, attaining a total worth of $1.7 trillion. Currently, food accounts for roughly 8% of overall international merchandise trade, up from 6% in 2000

In the fast-paced world of food exports, traceability has become a cornerstone of operational success. But what exactly is traceability, and why is it so critical?

Traceability in the food export market refers to the ability to track and verify every step of a food product’s journey from its source—whether that’s a farm, factory, or supplier—right through to the final destination, such as a grocery store or restaurant. It’s all about knowing where your product has been, how it’s been handled, and whether it meets the necessary standards.

This process is more than just a paperwork requirement—it’s about accountability, safety, and quality assurance. Traceability ensures that every batch of food can be traced back to its origin, which is crucial in the event of a recall or quality concern.

In the food export industry, maintaining traceability can be difficult. Many exporters deal with fragmented food supply chains involving multiple farmers, producers, processors, and distributors. This lack of integration makes it hard to gather accurate data in real time, increasing the chances of errors or miscommunication. A misplaced batch number or incorrectly labeled product can lead to confusion, compliance issues, and potential risks to consumer safety.

For example, let’s say there’s an outbreak of foodborne illness linked to a specific batch of imported fruits. If the exporter doesn’t have accurate traceability records, tracing the origin of the contaminated fruit becomes a nightmare. This not only increases the time to address the issue but could also damage the company’s reputation.

Additionally, inconsistent data or reliance on manual systems can slow down the entire process. The risk of data errors is high, making it harder to comply with regulations, deliver goods on time, and maintain consumer trust.

So, in an industry where transparency is becoming non-negotiable, food exporters need to invest in systems that offer seamless traceability to meet these demands head-on.

In the food export market, traceability is a vital part of ensuring safety, quality, and compliance. But despite its importance, many food exporters face a number of challenges in maintaining full traceability throughout their supply chains.

One of the biggest hurdles for food exporters is a lack of end-to-end traceability. This happens when information about a product is fragmented across different stages of the supply chain—meaning that one part of the process may have detailed data, but another part doesn’t.

For example, a farm might have records about the crops it’s producing, but that information doesn’t always make it to the processing plant, and from there, it might not get to the distributor. This results in incomplete or missing data, making it difficult to track the product’s journey in case of a recall or quality issue.

Having fragmented data also means it can be much harder to respond quickly to consumer or regulatory questions about a product’s origin, handling, or safety. The more disconnected the supply chain, the more at risk a company is for non-compliance and operational inefficiencies.

Food exporters often deal with complex supply chains that involve multiple intermediaries. Each step of the chain—from farms and processors to distributors and retailers—can involve different systems, standards, and record-keeping methods. Without a unified, integrated system to connect these parts, it’s easy for valuable data to fall through the cracks.

This lack of integration can create confusion, delays, and mistakes that ultimately hurt business operations. It also makes it harder to prove compliance with international regulations or to respond to consumer concerns swiftly.

Missing or incomplete records are another major challenge in food traceability. Data errors, lost documents, or human mistakes can happen at any point in the supply chain. When that happens, it becomes incredibly difficult—if not impossible—to prove the origin, handling, and safety of a product.

This is particularly dangerous when it comes to global regulations that demand proof of food safety, ethical sourcing, and sustainability. A missing batch number or incomplete shipment record could lead to non-compliance and the inability to verify that the product meets the necessary standards. The impact can be both financial and reputational.

Regulations like the FSMA (Food Safety Modernization Act) and EUDR (EU Deforestation Regulation) have stringent traceability requirements that must be met to ensure products are safe, sustainable, and ethically sourced.

For example, the FSMA mandates that food exporters must be able to track their products throughout the entire supply chain, from farm to table. This includes knowing the origin of ingredients, how they were processed, and the conditions under which they were stored and transported. Any missing link in the chain can lead to compliance failures.

Non-compliance with regulations can have significant consequences for food exporters. For one, there are financial penalties, such as fines, for not meeting regulatory standards. But there’s also a risk to a company’s reputation. If an issue arises and an exporter can’t prove where a product came from or how it was handled, it damages trust with both consumers and regulators.

Today’s consumers are increasingly concerned about the products they buy, particularly when it comes to food. They want to know where their food comes from, how it’s produced, and whether it’s safe, sustainable, and ethically sourced. This growing demand for transparency in the food supply chain puts pressure on food exporters to provide clear, verifiable information.

The link between traceability and consumer confidence is clear: if a consumer can trace a product’s journey from farm to table, they are much more likely to trust the brand. Transparency builds loyalty, strengthens brand reputation, and increases consumer confidence. On the other hand, if a company can’t provide this information, it risks losing consumer trust—and ultimately sales.

The demand for this level of transparency is only expected to grow as consumers become more socially and environmentally conscious. Food exporters must ensure they have systems in place that can meet these expectations or risk falling behind competitors.

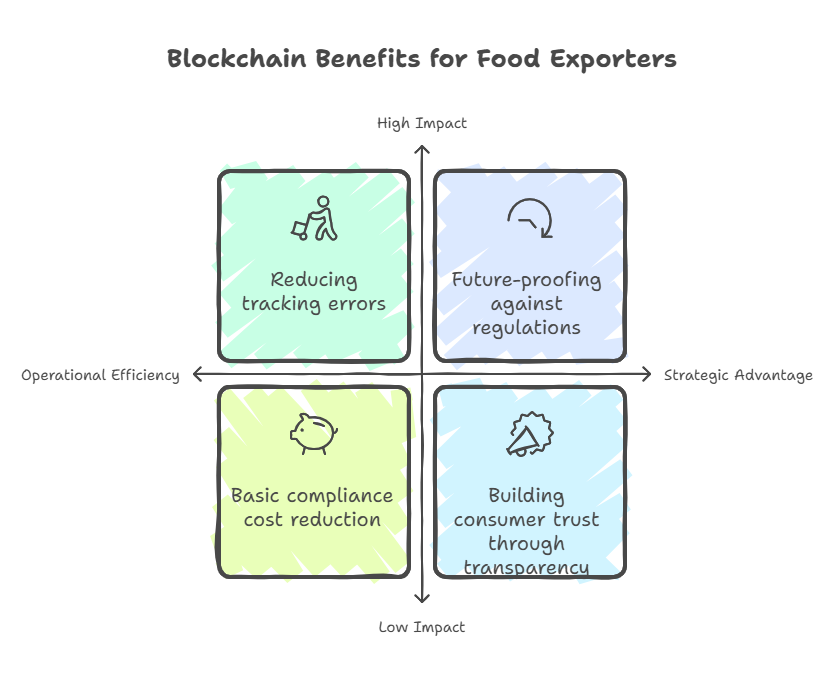

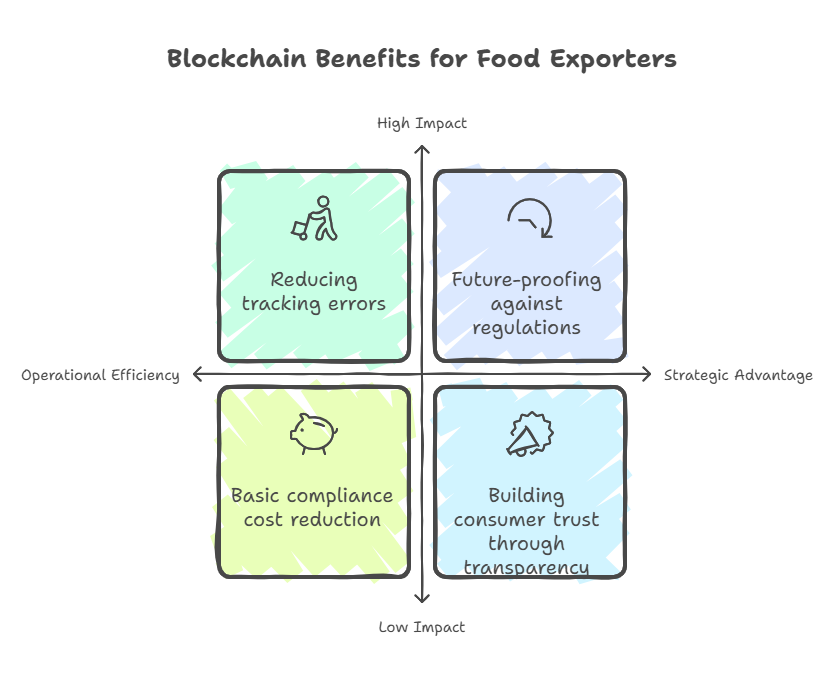

At its core, blockchain is a decentralized digital ledger that securely records transactions. In the context of food exports, blockchain’s primary benefit is its ability to provide real-time, immutable records of a product’s journey—from farm to table.

Once a piece of data (like the origin of a crop, the processing details, or shipping information) is entered into the blockchain, it cannot be altered. This creates a transparent, tamper-proof history for every batch of food. Every participant in the supply chain, from farmers to processors to exporters, can access this data and verify it in real time. The beauty of blockchain is that it offers this level of transparency without relying on a central authority, reducing the chance of errors or fraud.

Food exporters must navigate a maze of global regulations—like FSMA (Food Safety Modernization Act) in the U.S. and EUDR in the EU—that require detailed and verifiable traceability of products. Blockchain technology simplifies this by offering a seamless way to track every step in the supply chain and automatically share relevant data with regulators.

For example, the FSMA requires food exporters to have clear, accurate records of their food products’ origins and safety protocols. Blockchain makes it easy for exporters to meet this standard by recording each transaction securely, so when regulators ask for documentation, it’s readily available in real time.

Likewise, under EUDR, companies need to demonstrate that the products they export (like coffee, cocoa, or soy) don’t contribute to deforestation. Blockchain ensures that food exporters can prove their products meet these stringent environmental requirements by offering transparent, tamper-proof data on sourcing and production practices.

In today’s market, consumers expect more than just a product—they want to know where it came from, how it was made, and whether it aligns with their values. Blockchain technology addresses these demands by providing a transparent, traceable journey for every food item.

For example, when a consumer buys a coffee bag, they can scan a QR code to see the exact farm where the beans were grown, the environmental practices used, and even the fair trade certifications. This transparency builds consumer trust. Brands that use blockchain to provide this level of detail tend to experience increased loyalty, as consumers feel more confident in their purchases.

Green Earth Fresh Produce (GEFP), based in the Nilgiris, partners directly with smallholder farmers to grow Iceberg lettuce. As a key supplier to Vista Process Foods, which supplies major brands like McDonald’s and KFC, GEFP leverages TraceX’s food traceability and farm management platform to optimize their entire supply chain. This platform streamlines farm and crop management, production planning, processing, and distribution, creating a comprehensive digital footprint for their product.

Before diving into new technology, it’s important to take a step back and assess where your current traceability system stands. What are the pain points you’re facing? Are your records fragmented across different systems? Do you have a hard time meeting global regulations, like FSMA or EUDR, with your current system?

Key areas where blockchain can help:

By pinpointing these gaps, you can focus on how blockchain will improve these areas and enhance your overall traceability.

Now that you understand your current challenges, it’s time to choose the right blockchain solution. Not all blockchain platforms are created equal, and you’ll need to pick one that fits your business needs, whether you’re an exporter, processor, or producer.

Factors to consider when selecting a blockchain solution:

At TraceX, our blockchain-based platform offers end-to-end traceability for the food supply chain, helping businesses comply with international standards while offering real-time, verifiable data. It’s designed to integrate smoothly into your existing systems and is user-friendly for all levels of users in your supply chain.

Once you’ve chosen the platform, the next step is to integrate it into your operations. This might seem like a heavy lift, but the goal is to make sure the blockchain system works seamlessly with your existing processes.

Key considerations for integrating blockchain:

Integration can be a bit of a transition, but once you have everyone on board and the technology in place, you’ll start to see how smooth and transparent your operations become.

Blockchain is not a “set it and forget it” solution. After implementation, you’ll need to continuously monitor and report your progress. The good news is that blockchain makes this easy by providing real-time, immutable records of all activities along the supply chain.

How to track progress and ensure ongoing compliance:

The transparency blockchain provides doesn’t just help with compliance; it also helps keep your brand trustworthy in the eyes of consumers, who increasingly demand more information about the food they buy.

In today’s global food export market, traceability is no longer a luxury—it’s a necessity. As regulations tighten and consumer demands for transparency rise, food exporters must address traceability challenges head-on. Blockchain technology offers a robust solution, providing real-time, secure data that ensures compliance, enhances transparency, and builds consumer trust. By implementing blockchain-based traceability systems, food exporters can not only meet regulatory requirements but also position themselves as leaders in the evolving marketplace.

Traceability ensures compliance with international regulations, boosts consumer confidence, and helps exporters manage risks such as contamination or fraud. It also allows brands to provide transparency on sourcing, production, and distribution processes.

Blockchain provides an immutable, real-time record of every transaction in the supply chain. This ensures that data is accurate, easily accessible, and transparent, which is crucial for compliance with regulations like FSMA and EUDR.

Blockchain offers several key benefits: it streamlines the process of ensuring compliance with global regulations, improves operational efficiency, enhances transparency for consumers, and reduces the risk of fraud or data manipulation in the supply chain.