Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Discover essential insights and practical steps in our EUDR Rubber Regulations Compliance Handbook. Learn how to meet EU deforestation-free requirements, enhance traceability, and ensure your rubber supply chain aligns with the latest sustainability standards.

The rubber industry is facing a seismic shift with the enforcement of the EUDR Rubber Regulations. For businesses across the rubber value chain, this regulation is not just another compliance hurdle—it’s a critical turning point that will shape the future of trade with the European market. Imagine losing access to one of the world’s largest markets because your supply chain isn’t transparent enough.

The EU, with its stringent environmental and social governance standards, is now demanding that every kilogram of rubber imported into its borders be fully traceable and verified as deforestation-free. For companies, failure to comply could mean hefty fines, damaged reputations, and, most critically, losing the trust of customers and partners.

According to Carbon Brief, new research reveals that rubber plantations in Southeast Asia have contributed to the loss of over 4 million hectares of tropical forests in the past three decades. This alarming figure highlights the urgent need for sustainable rubber production and stricter regulations to protect biodiversity.

The European Union Deforestation Regulation (EUDR) is a bold initiative designed to curb the importation of products linked to deforestation and forest degradation. To be enforced since from 31/12/24, the regulation aims to ensure that commodities entering the EU market, including rubber, are sustainably sourced and free from deforestation or environmental harm.

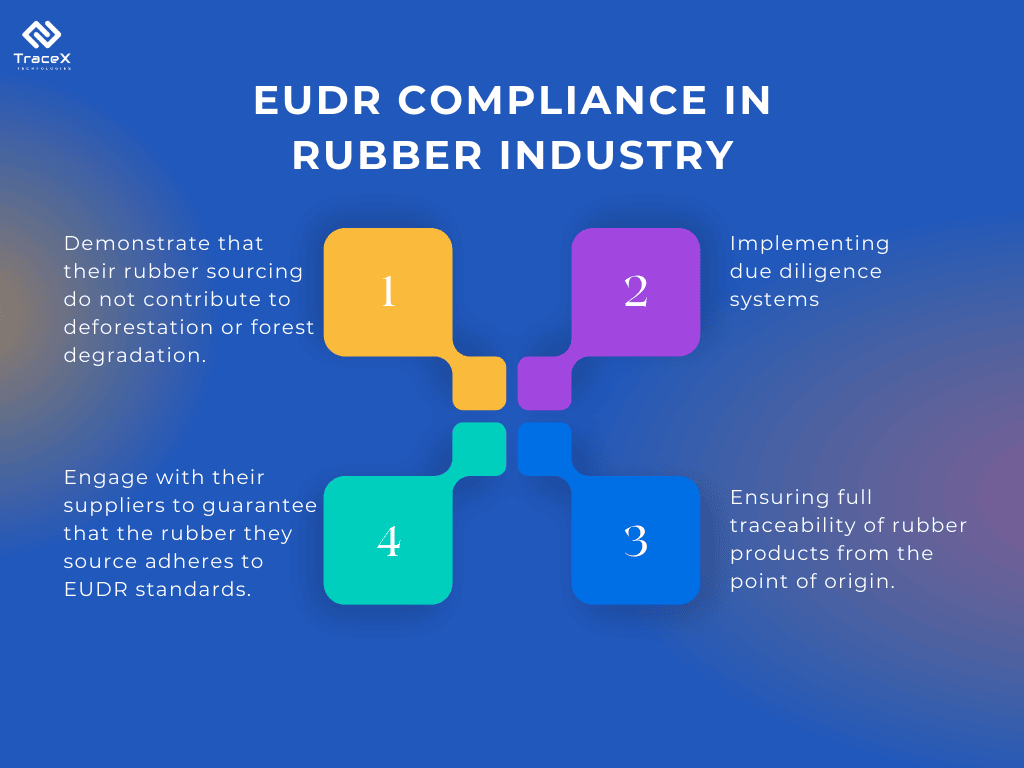

The EUDR demands that companies importing rubber into the EU provide verifiable evidence that their products do not contribute to deforestation. This includes a robust system of traceability, transparency, and due diligence throughout the supply chain

Key Takeaways

For the rubber industry, this regulation is a game-changer. Historically, rubber sourcing has been associated with deforestation, habitat destruction, and social exploitation. With the EUDR, the EU is setting a high bar, pushing businesses to adopt more sustainable practices or face significant consequences.

One of the cornerstones of the EUDR is traceability. Companies must be able to trace the rubber back to its source, ensuring it comes from land that is not linked to deforestation after [insert reference year, e.g., 2020]. This requires a thorough documentation process, where every step from harvesting to processing and transportation is recorded and verifiable.

EUDR mandates businesses to conduct rigorous risk assessments of their supply chains. This means identifying any potential risks related to deforestation and implementing measures to mitigate them. Companies must also establish a due diligence system that continuously monitors and evaluates their supply chains to ensure ongoing compliance.

Regular reporting to the EU authorities is required under the EUDR. Businesses must submit detailed reports that include data on sourcing practices, risk assessments, and the steps taken to ensure compliance. These reports are subject to audits and must be backed by verifiable data.

The European Union Deforestation Regulation (EUDR) has significant implications for rubber importers and exporters, particularly those trading with the lucrative EU market. The regulation mandates that companies conduct thorough due diligence to ensure their rubber products are not linked to deforestation or forest degradation after December 31, 2020. This includes providing detailed information on supply chains, assessing risks, and implementing mitigation strategies such as supplier collaboration and audits.

Failure to comply can lead to penalties, confiscation of goods, and even temporary or permanent bans on trading in the EU.

With December 2024 as a deadline for large companies and until June 2025 for SMEs, rubber importers and exporters must act quickly to establish robust traceability systems, collect geolocation data, and demonstrate the legality and sustainability of their rubber sources. Adapting to the EUDR presents both challenges and opportunities for the rubber industry to enhance transparency, strengthen supplier relationships, and position themselves as responsible players in the global market.

1. Conduct a Comprehensive Supply Chain Audit

The first step towards EUDR compliance is understanding your current supply chain. Conduct a thorough audit to identify all suppliers, assess their practices, and determine the level of traceability currently in place. This audit will help you identify gaps in your supply chain that need to be addressed.

2. Invest in Traceability Technology

Blockchain and other traceability technologies are essential tools for EUDR compliance. These technologies enable you to create an immutable record of every transaction and movement within your supply chain, from the point of harvest to the final product. By leveraging these tools, you can ensure that your rubber is sourced responsibly and transparently.

3. Develop a Risk Management Strategy

Create a comprehensive risk management strategy that includes regular assessments of your supply chain for deforestation risks. This strategy should outline the steps your business will take to mitigate identified risks, such as switching to certified suppliers, enhancing monitoring practices, and improving communication with stakeholders.

4. Collaborate with Suppliers and Stakeholders

EUDR compliance is not something that can be achieved in isolation. Work closely with your suppliers to ensure they understand and meet the requirements of the regulation. Provide training and support where needed and encourage them to adopt sustainable practices. Collaboration with industry bodies, NGOs, and government agencies can also help you stay informed about best practices and emerging trends in compliance.

5. Regular Reporting and Continuous Improvement

Compliance with the EUDR is an ongoing process. Establish a system for regular reporting to the EU authorities, and ensure that all required data is collected, verified, and submitted on time. Additionally, continuously monitor your supply chain for changes or new risks, and be prepared to adjust your practices as needed to maintain compliance.

The introduction of EUDR has far-reaching implications for global rubber supply chains. The regulation mandates that all rubber products imported into the EU must be free from links to deforestation. This requirement has prompted companies to re-evaluate their supply chains and seek out suppliers who can provide verified, deforestation-free rubber. Additionally, EUDR has increased the demand for transparency and traceability in supply chains, pushing companies to adopt new technologies and processes to meet these expectations. For businesses, this means that compliance with EUDR is not just a regulatory requirement but a competitive advantage in a market increasingly driven by sustainability.

The EU Deforestation Regulation (EUDR) has significant implications for Indian rubber producers, as it mandates strict traceability and sustainability standards for rubber imported into the European Union. Indian producers must now ensure that their rubber is sourced from deforestation-free areas, with comprehensive documentation to prove compliance. This regulation necessitates greater transparency and rigorous supply chain management, posing challenges for smaller producers. However, it also presents an opportunity for Indian rubber producers to adopt sustainable practices, potentially gaining a competitive edge in the global market by aligning with international standards.

Sourcing rubber sustainably and ethically is more than just a regulatory requirement under EUDR; it is also a key component of corporate social responsibility. Companies can adopt several strategies to ensure their rubber sourcing aligns with EUDR standards, including working closely with suppliers to promote sustainable practices, investing in certification schemes, and supporting smallholder farmers in adopting deforestation-free practices. Additionally, businesses should prioritize transparency in their supply chains and engage with stakeholders to ensure that all parties are committed to sustainable and ethical sourcing. These strategies not only help companies comply with EUDR but also enhance their brand reputation and market competitiveness.

Rubber offers smallholders a lucrative income source while providing numerous environmental benefits. Compared to pineapple, rubber plantations store significantly more carbon, reduce pesticide use, and promote biodiversity through intercropping and agroforestry practices.

Certification schemes such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) can play a crucial role in demonstrating compliance with the EUDR. These certifications provide assurance that your rubber is sourced from sustainably managed forests and meets the standards set by the EU.

Engaging third-party auditors to assess your compliance can provide an additional layer of assurance. These audits can identify potential weaknesses in your compliance strategy and offer recommendations for improvement. They also demonstrate to regulators and customers that your business is committed to meeting the highest standards of sustainability and transparency.

One of the biggest challenges in the rubber industry is its complex and fragmented supply chains. Rubber is often sourced from smallholder farms in remote areas, making traceability a daunting task. The lack of digital infrastructure in these regions further complicates the ability to monitor and verify the origin of rubber.

Implementing the necessary systems for traceability and due diligence can be expensive. Small and medium-sized enterprises (SMEs), in particular, may struggle with the financial burden of upgrading their operations to meet EUDR standards. These costs can include investments in technology, training, and the hiring of compliance officers.

The EUDR is a relatively new regulation, and its enforcement mechanisms are still evolving. Businesses may find it challenging to navigate the legal intricacies of compliance, especially when dealing with different national interpretations of the regulation. This uncertainty can lead to hesitation in making the necessary changes, putting businesses at risk of non-compliance.

Traceability is a cornerstone of EUDR compliance for rubber products. By tracking the journey of rubber from source to market, businesses can ensure that it meets sustainability standards and is not associated with deforestation. Traceability systems enable companies to identify and address potential risks, demonstrate compliance, and build trust with consumers.

Blockchain traceability solutions play a crucial role in ensuring EUDR compliance by providing transparent, immutable records of the entire supply chain. These solutions enable businesses to track the journey of commodities like soy, palm oil, coffee, and rubber from origin to final destination, ensuring they meet the EU’s deforestation-free requirements. By capturing real-time data and automating verification processes, blockchain enhances the accuracy and reliability of compliance reporting, reduces the risk of fraudulent activities, and fosters trust among stakeholders, ultimately supporting sustainable and responsible sourcing practices.

TraceX’s EUDR compliance software is designed to help businesses in the rubber industry meet the stringent requirements of the EU Deforestation Regulation (EUDR). Here’s how it facilitates rubber compliance:

By integrating these features, TraceX’s EUDR compliance software supports the rubber industry in maintaining deforestation-free supply chains, ensuring adherence to EUDR regulations, and promoting sustainable sourcing practices.

Adapting to EUDR regulations requires a proactive approach from businesses in the rubber industry. This involves staying informed about regulatory changes, regularly auditing supply chains for compliance, and investing in the necessary technologies and processes to meet EUDR standards. Companies should also consider developing a comprehensive EUDR compliance plan that includes training for employees, supplier engagement, and continuous improvement of sustainability practices. By taking these steps, businesses can not only meet the immediate requirements of EUDR but also position themselves as leaders in the industry’s transition to sustainability.

EUDR compliance is more than just a regulatory obligation; it is an opportunity for the rubber industry to lead the way in sustainability and ethical sourcing. By understanding the key considerations, leveraging technology like blockchain, and adopting sustainable sourcing strategies, companies can not only meet EUDR requirements but also enhance their competitive edge in a rapidly evolving market. The road to compliance may be challenging, but with the right strategies and tools in place, businesses can navigate the complexities of EUDR and contribute to a more sustainable future for the rubber industry.

The EUDR mandates that rubber imported into the EU must be sourced from deforestation-free areas, with full traceability and documentation to prove compliance. Producers must also conduct due diligence to ensure that their supply chains meet these standards.

Indian rubber producers can achieve EUDR compliance by implementing robust traceability systems, conducting supplier due diligence, ensuring transparency in their supply chains, and adopting sustainable sourcing practices that meet deforestation-free requirements.

Non-compliance with the EUDR can result in significant penalties, including fines, restrictions on market access, and reputational damage. It may also lead to the suspension or rejection of rubber shipments to the EU, affecting business operations and profitability.