Contact: +91 99725 24322 |

Menu

Menu

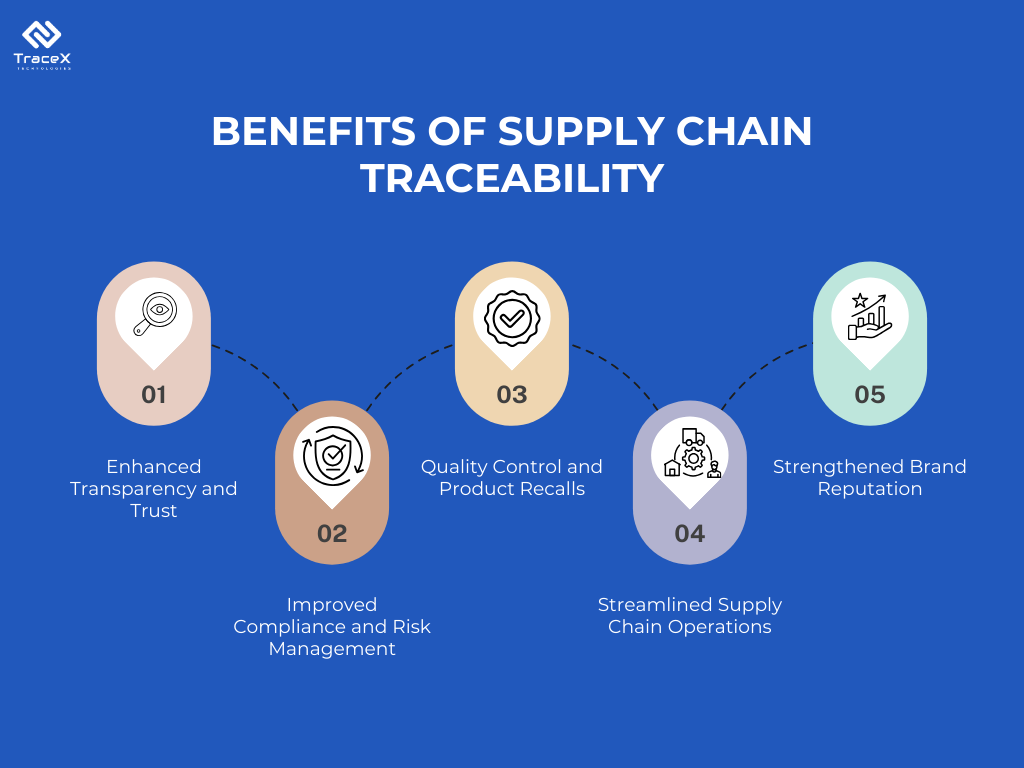

Today supply chain traceability has emerged as a critical component of successful business operations. At its core, traceability refers to the ability to track a product’s journey from its origin to the end consumer. This transparency is no longer just a luxury but a necessity, particularly as consumers become increasingly conscious of ethical sourcing, environmental sustainability, and regulatory compliance.

According to PWC, while cost-of-living pressures weigh, some consumers say they are willing to spend 9.7% more, on average, for sustainably produced or sourced goods, as almost nine-in-ten (85%) report experiencing first-hand the disruptive effects of climate change in their daily lives

With the growing scrutiny from both consumers and regulatory bodies, companies risk facing backlash and potential financial penalties if they cannot demonstrate transparency in their supply chains. In a landscape where one misstep can lead to damaged reputations, understanding and implementing effective traceability is paramount. This guide aims to demystify the concept of supply chain traceability, exploring its importance in fostering consumer trust, ensuring compliance, and promoting sustainability.

Key Takeaways

Supply chain traceability refers to the ability to track and document the journey of a product from its origin through every stage of the supply chain until it reaches the end user. This involves various components:

Together, these elements create transparency, foster consumer trust, and enhance sustainability throughout the supply chain.

Product Traceability is all about knowing where a product comes from and where it goes. Think of it like following a treasure map. Each step of the journey—from the farm or factory to the store shelves—needs to be documented. This tracking helps businesses understand their products’ lifecycle, which is crucial for ensuring quality and safety. If something goes wrong, like a food safety issue, companies can quickly pinpoint where the problem originated and take action. This level of transparency builds trust with consumers, who want to know that the products they buy are safe and ethically sourced.

Material Traceability involves digging deeper into the ingredients or materials that make up a product. For example, if a company is using organic cotton for its clothing, material traceability ensures that this cotton is sourced from farms that follow organic practices. Understanding where materials come from and how they are processed is essential for businesses to maintain compliance with regulations and certifications. It also helps companies minimize their environmental impact by choosing sustainable materials and processes.

Supplier Mapping is about identifying and evaluating the suppliers in your supply chain. Imagine trying to put together a puzzle without knowing where each piece came from. Supplier mapping provides a clear view of who supplies your materials, how they operate, and their compliance with standards. It allows companies to assess risks associated with each supplier, such as their labor practices, environmental impact, or financial stability. By having this information, businesses can make informed decisions, ensuring they partner with responsible suppliers who align with their values.

In summary, understanding these aspects of traceability is crucial for modern businesses. They not only help in managing risks and compliance but also foster trust and sustainability throughout the supply chain.

Commodity traceability is the process of tracking the journey of raw materials and products—like agricultural goods, minerals, and manufactured items—through the entire supply chain. This traceability is crucial in sectors like agriculture and manufacturing, where the quality, safety, and sustainability of products can have significant impacts on both businesses and consumers. For example, in agriculture, knowing where a crop was grown, how it was processed, and how it reached the consumer can help ensure food safety and compliance with regulations.

On the flip side, when commodity traceability is done right, the benefits are immense. One of the most significant advantages is risk management. By having a clear view of the entire supply chain, businesses can identify potential risks related to sourcing practices, environmental impact, or supplier reliability. If an issue arises, such as a recall due to contamination, companies can quickly trace back to the source and address the problem more effectively.

Quality assurance is another key benefit. With effective traceability, businesses can ensure that the commodities they source meet their quality standards. This is especially important in sectors like food and beverage, where the quality of raw materials directly affects the final product. By tracking commodities from farm to table, companies can assure customers that they are receiving safe and high-quality products.

In conclusion, commodity traceability is essential for navigating the complexities of modern supply chains. While challenges like lack of transparency and data management exist, the benefits of risk management and quality assurance make it a worthwhile investment for businesses. By adopting effective traceability practices, companies can not only enhance their operational efficiency but also build trust with consumers who increasingly demand transparency and accountability.

Supply chain provenance refers to the ability to trace the history and journey of a product from its origin to the final consumer. It encompasses everything from how raw materials are sourced and processed to where and how they are manufactured, packaged, and distributed. This transparency is increasingly relevant in today’s marketplace, where consumers are more informed and concerned about the origins of the products they buy.

For consumers, provenance provides essential information that helps them make informed choices. In an age where ethical considerations like sustainability, fair trade, and environmental impact are paramount, knowing the provenance of a product can significantly influence purchasing decisions. For instance, a consumer might be more likely to choose a chocolate brand that sources its cocoa from sustainable farms over one that does not disclose its sourcing practices.

For businesses, understanding supply chain provenance can lead to numerous advantages. It allows companies to demonstrate compliance with regulations, enhance product quality, and meet consumer expectations for transparency. Furthermore, businesses that invest in tracking and showcasing their provenance can differentiate themselves in a crowded marketplace, potentially leading to increased customer loyalty and brand recognition.

Supply chain provenance is also a powerful tool for enhancing brand reputation. When a company can effectively communicate the story behind its products, it builds trust with consumers. Transparency fosters a connection; when customers know where their products come from and the ethical practices behind them, they are more likely to develop a loyal relationship with the brand.

Take the example of Patagonia, an outdoor clothing company that is renowned for its commitment to sustainability and ethical sourcing. Patagonia openly shares information about its supply chain, from the raw materials used to the factories that produce their clothing. This transparency has not only bolstered their reputation but also attracted a customer base that values sustainability.

Green Earth partnered with TraceX to implement advanced traceability solutions in their fresh produce sector, aiming to enhance food safety, quality, and transparency. With TraceX’s blockchain-powered platform, Green Earth was able to digitize and streamline its supply chain processes, making it easier to track produce from the farm to the consumer. This digital transformation helped them monitor every step of the supply chain, ensuring that information regarding sourcing, processing, and distribution was accessible and verifiable in real time.

Batch traceability is the ability to track a specific batch of products throughout the supply chain, from production to distribution to the end consumer. Each batch is assigned a unique identifier that allows businesses to monitor its journey and ensure quality control at every stage. This is crucial for maintaining standards and compliance with regulations.

By tracking batches, companies can quickly identify and address any quality issues. If a problem arises—such as contamination in a food product—batch traceability allows businesses to isolate the affected batch and take immediate corrective action. This proactive approach not only safeguards consumers but also protects the brand’s reputation.

Batch traceability also plays a critical role in managing recalls and audits. If a product needs to be recalled, businesses can use batch tracking to identify affected products quickly. This not only helps minimize risk but also reduces the costs associated with widespread recalls. Efficient traceability systems can significantly cut down on the time it takes to locate and remove faulty products from the market, ensuring consumer safety and regulatory compliance.

During audits, having a robust batch traceability system demonstrates to regulators that a company takes quality control seriously. It shows that the business has thorough processes in place to monitor its products, which can help avoid penalties and reinforce consumer trust. Batch traceability is a vital aspect of supply chain management that enhances quality control, especially in critical industries like food and pharmaceuticals.

Chain of Custody in supply chain traceability refers to the process of maintaining and documenting the handling of products or materials as they move through the supply chain. This ensures that there is a clear record of who has possession of a product at each stage, along with details about its condition and any transformations it undergoes. This documentation is crucial for verifying the integrity and authenticity of products, especially in industries like food, pharmaceuticals, and luxury goods, where traceability is essential for compliance and consumer trust.

In today’s supply chain landscape, real-time monitoring has become crucial for effective traceability. It allows businesses to track their products and materials at every stage of the supply chain in real time, providing instant visibility into operations. This capability helps companies respond quickly to any issues that arise, whether it’s a delay in delivery, a sudden temperature change in perishable goods, or a compliance concern. By having up-to-the-minute data, businesses can make informed decisions, reduce waste, and improve overall efficiency.

Real-time monitoring is essential for effective supply chain traceability, leveraging technologies like IoT, RFID, and blockchain to provide instant visibility and responsiveness. By implementing these technologies, businesses can enhance their operations, ensure product quality, and build consumer trust.

Supply chain traceability is crucial for compliance and due diligence for several reasons:

Selecting the right traceability solution is essential for ensuring effective supply chain management. Here are key factors to consider:

TraceX offers advanced platforms for food traceability and EUDR compliance that tackle challenges in supply chain transparency. By leveraging blockchain technology, the platforms provide secure, real-time data on product origins, ensuring accountability and sustainability throughout the supply chain. Key features include automated reporting tools for EUDR compliance, which help businesses document and verify their supply chain practices. This enables companies to mitigate risks, improve efficiency, and enhance consumer trust while meeting regulatory requirements

Supply chain traceability is more than just a regulatory requirement; it’s a cornerstone of consumer trust and sustainable practices. By implementing effective traceability systems, businesses can enhance transparency, mitigate risks, and ensure compliance with regulations like EUDR. As you move forward, prioritizing traceability not only safeguards your operations but also fosters confidence among consumers and stakeholders alike. Embrace the tools and technologies available to create a resilient and transparent supply chain that stands the test of time.

Supply chain traceability refers to the ability to track and trace the entire lifecycle of a product, from its origin to the end consumer. It involves documenting the movement of products, materials, and information throughout the supply chain.

Traceability is crucial for compliance with regulations, enhancing consumer trust, improving risk management, and ensuring quality control. It also supports transparency into sustainable sourcing and production practices.

Businesses can implement effective traceability systems by leveraging technologies like blockchain, IoT, and cloud-based solutions. It’s essential to start small, train staff, and continuously monitor and adapt the system to meet evolving needs.

WhatsApp us