Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Discover how global traceability standards like GS1, ISO 22005, FSMA, and HACCP are transforming supply chains, ensuring transparency, compliance, and sustainability for businesses worldwide.

Consumers today demand to know where their products come from, how they’re made, and whether they align with ethical and sustainable practices. Yet, many businesses struggle with achieving this level of transparency due to fragmented supply chains, inconsistent data, and a lack of unified frameworks. traceability standards come into play, acting as a blueprint for building trust and accountability in supply chains.

Without these standards, companies face risks such as non-compliance with regulations, reputational damage, and inefficiencies that eat into profits. But with the right traceability standards, businesses can turn transparency from a challenge into a competitive advantage. In this blog, we’ll explore how adopting global traceability standards can transform supply chains and unlock new opportunities for growth and sustainability.

Key Takeaways

Imagine being able to follow a product’s journey through every step of its life—from raw material to the final product on store shelves. That’s what traceability in supply chains is all about! It’s the ability to track and trace goods as they move through various stages of production, processing, and distribution.

Now, why is this so important? Because traceability ensures that every product meets the standards for safety, quality, and sustainability. Global traceability standards make this possible by providing a common framework for businesses around the world to follow.

Traceability is like giving every product its own story. It’s the process of recording and managing information about a product’s origins, movement, and transformations throughout the supply chain. Think of it as a way to answer critical questions like:

This information is crucial for businesses to ensure quality, manage risks, and address recalls quickly when something goes wrong.

To make traceability work across industries and borders, global organizations have developed traceability standards.

GS1 is a global organization that develops standards for business communication, including barcodes and product identifiers.

This standard focuses on traceability in food and feed supply chains.

A U.S.-based regulation designed to enhance food safety through better traceability.

A global system for food safety that relies on traceability to monitor critical control points in food production.

These standards are designed to solve big challenges in today’s supply chains. Here’s how they help:

Traceability standards aren’t just technical guidelines—they’re tools for building safer, more sustainable, and reliable supply chains. By adopting these standards, businesses can create trust, meet regulatory demands, and contribute to a better future for everyone.

Ever wondered what’s behind the products you buy? From the food on your plate to the clothes you wear, there’s an entire journey that each item takes to get to you. Transparency in supply chains means making that journey clear and open for everyone—consumers, businesses, and regulators alike. And here’s why it’s so important:

We’ve all heard stories of fake products or unethical practices in industries like food, fashion, or electronics. For consumers, knowing where products come from and how they’re made builds trust in a brand.

Think about it: Would you rather buy coffee that says “sustainably sourced from ethical farms” or one with no information at all? Transparency allows businesses to tell their story, show their values, and connect with customers on a deeper level.

A leading spice processor from Karnataka, India, with operations in Vietnam and Turkey, adopted TraceX’s Sustainability Platform to ensure product authenticity and safety. Known for their focus on quality and sustainability, the company used TraceX’s advanced traceability solutions to enhance transparency across their supply chain, verify the origin of their spices, and ensure compliance with global standards. This initiative reinforced their commitment to delivering safe, high-quality products while building trust with consumers and stakeholders.

In today’s world, governments are stepping up to ensure products meet sustainability and ethical standards. Take the EU Deforestation Regulation (EUDR), for example. It requires companies to prove that their raw materials, like soy, rubber, or coffee, don’t contribute to deforestation.

Without transparency, meeting such regulations is nearly impossible. Clear and traceable supply chains help businesses stay compliant, avoid fines, and maintain their license to operate.

No company wants to deal with fraud, contamination, or ethical scandals. These issues can lead to financial losses, damaged reputations, and even legal troubles.

For instance, if a contaminated batch of food enters the market, how quickly a company can trace the problem and remove the product could mean the difference between a minor recall and a major crisis. Transparency makes it easier to identify problems early, take action, and prevent them from escalating.

Transparency isn’t just a “nice-to-have” anymore—it’s a must-have. It builds consumer trust, keeps businesses on the right side of the law, and protects them from risks. Whether it’s meeting regulatory demands, proving ethical sourcing, or managing a crisis, transparency is the foundation of modern, responsible supply chains.

When everyone knows what’s happening at every step of the process, the entire system becomes more trustworthy, sustainable, and resilient. And that’s a win for businesses, consumers, and the planet alike!

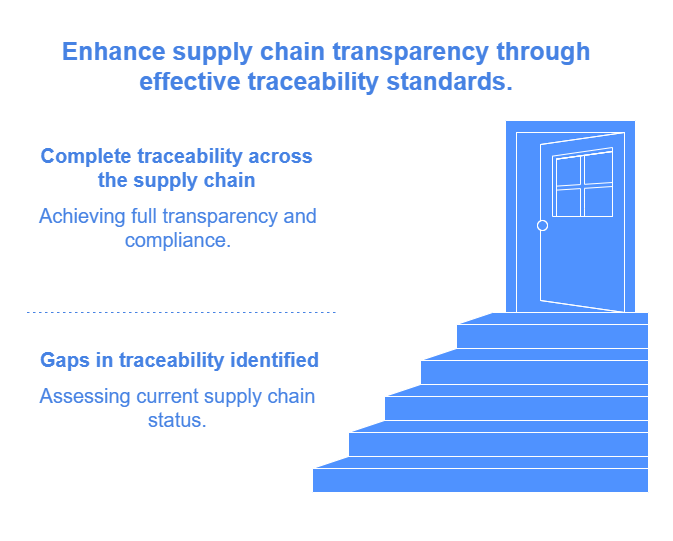

Implementing traceability standards sounds like a great idea—it ensures transparency, builds trust, and keeps businesses compliant. But the road to achieving it is not without bumps. Here’s a closer look at the challenges companies face when trying to make their supply chains traceable.

Let’s face it: adopting traceability standards isn’t cheap. Setting up systems to track and record every step of your supply chain requires significant investment in technology, training, and manpower.

For smaller businesses, this can feel overwhelming. They might ask, “Do we really have the budget for this right now?” Even larger companies need to justify the costs and ensure they’re getting a return on investment.

But here’s the thing: while the upfront costs can be high, the long-term benefits—avoiding penalties, earning consumer trust, and staying competitive—usually outweigh them.

Most companies already have systems in place to manage their operations, and introducing new traceability tools can feel like trying to fit a square peg in a round hole.

For example, let’s say a company uses a legacy system to manage inventory. Now they’re expected to incorporate advanced blockchain traceability or digital MRV tools. Making these systems work together seamlessly can be tricky. It often requires IT upgrades, retraining employees, and restructuring workflows, which can cause delays or temporary inefficiencies.

Supply chains aren’t simple. Raw materials might come from one country, be processed in another, and sold in a third. Add to that multiple suppliers, middlemen, and third-party logistics providers, and you’ve got a complex web of players.

Collecting and managing data from each tier—especially when some suppliers still use manual processes or aren’t technologically advanced—can be a logistical nightmare. Ensuring the data is accurate, timely, and trustworthy across such a fragmented chain requires significant coordination and trust-building.

While these challenges are real, they’re not insurmountable. Businesses need to approach traceability as a gradual transformation rather than a one-time fix. Start small, focus on high-impact areas, and work with partners and technology providers who understand your industry’s unique needs.

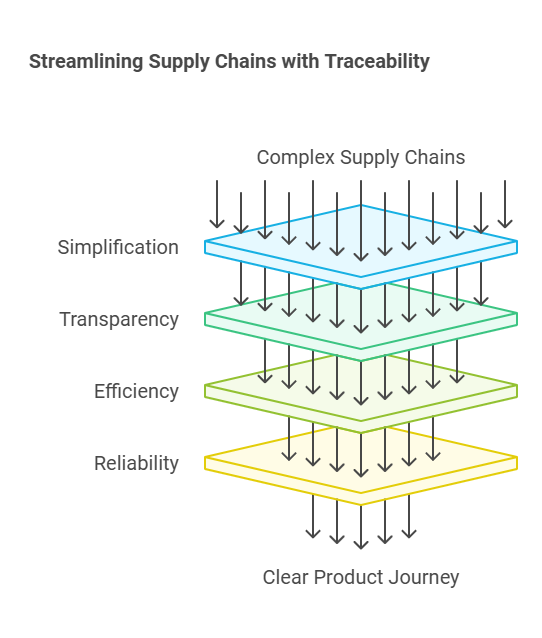

The challenges of implementing traceability might seem daunting, but that’s where global traceability standards come to the rescue. These standards are like the universal “language” of supply chains, designed to simplify processes, improve efficiency, and foster collaboration.

Imagine trying to communicate in a group where everyone speaks a different language—it’s chaos! This is what supply chains can feel like without standardization.

Global traceability standards, such as GS1 or ISO 22005, provide a common framework for all stakeholders to follow. Whether it’s a farmer, manufacturer, or retailer, everyone uses the same protocols for tracking and recording data. This shared understanding makes it easier to exchange information, track products, and ensure transparency across the entire supply chain.

For example, a barcode on a product can carry standardized data about its origin, processing, and journey—ensuring everyone is on the same page.

A big headache for companies is getting their systems to work together. A manufacturer’s software might not “talk” to a distributor’s database, leading to data silos and inefficiencies.

Traceability standards solve this by promoting interoperability. They define how data should be formatted, stored, and shared, making it easier for different systems to connect and communicate. This means you don’t need to overhaul your entire tech stack—standards help bridge the gaps between old and new systems.

The result? Smoother operations, fewer errors, and a supply chain that runs like a well-oiled machine.

Keeping up with regulations like the EU Deforestation Regulation (EUDR) or FSMA can be overwhelming, especially when requirements differ from one region to another.

Traceability standards act as a guide to help businesses meet these regulations. They ensure the data you collect is accurate, complete, and in the format required by authorities. Whether you’re tracking a product’s origin, ensuring sustainability claims, or managing recalls, these standards make compliance less of a burden.

For example, ISO 22005 focuses on food and feed traceability, helping businesses meet safety and sustainability requirements globally. This means you’re not just checking a box—you’re building trust with regulators, partners, and consumers.

For example, instead of manually updating spreadsheets, a standardized traceability system can automate tracking and provide real-time updates. This saves time, reduces costs, and ensures smoother operations from start to finish.

When you can show exactly where your products come from, how they were made, and how they’re sourced ethically, it sets you apart. Customers are more likely to choose brands they trust, boosting loyalty and word-of-mouth recommendations.

Imagine being able to say, “Here’s where your coffee beans were grown, and here’s how we ensure ethical practices at every step.” That’s a powerful message.

For instance, traceability standards can verify that wood comes from responsibly managed forests or that seafood is sourced without harming marine ecosystems. These efforts not only protect the planet but also align with consumer values and regulatory requirements like the EU Deforestation Regulation (EUDR).

For example, if one supplier consistently causes delays, the data will make it clear, allowing you to address the issue or switch to a more reliable partner. Over time, these small improvements add up to significant cost savings and higher profits.

Adopting these standards isn’t just a smart move—it’s a step toward building a better, more transparent future for your business and your customers.

Technology is the driving force that’s turning traceability from a challenging concept into an achievable reality. With the right tools, businesses can not only meet global traceability standards but also enhance their operations in ways that were unimaginable a few years ago.

Think of blockchain as a digital ledger that no one can tamper with. Every transaction or movement of a product is recorded in this ledger, creating a permanent and transparent history.

For example, in the food industry, blockchain can track a mango from the farm where it was grown to the store where it’s sold. If there’s ever a food safety issue, this technology allows companies to pinpoint the problem in seconds, not weeks.

Because blockchain records can’t be altered, it builds trust with regulators, partners, and consumers. Everyone knows the data is accurate, reliable, and tamper-proof.

The Internet of Things (IoT) brings traceability to life by collecting data directly from the field. IoT devices like sensors, GPS trackers, and RFID tags can monitor products in real time as they move through the supply chain.

Imagine a shipment of fresh seafood. IoT sensors can track the temperature of the shipment from the fishing boat to the warehouse to ensure it’s always stored under the right conditions. If there’s a temperature fluctuation, companies can take immediate action to prevent spoilage.

IoT doesn’t just help companies meet traceability standards—it also reduces waste and improves efficiency by ensuring products are handled properly every step of the way.

With so much data being collected, it can feel overwhelming to figure out what it all means. That’s where Artificial Intelligence (AI) steps in, turning raw data into actionable insights.

AI can analyze patterns in supply chains to predict potential disruptions or inefficiencies. For instance, it can identify bottlenecks in production or highlight suppliers that might pose risks. AI-driven analytics also help companies optimize their operations, ensuring smoother processes and better decision-making.

When combined with blockchain and IoT, AI adds another layer of intelligence, making traceability systems smarter and more proactive.

Adhering to global traceability standards can be a daunting task for businesses. From managing complex supply chains to ensuring compliance with evolving regulations, the challenges are many. TraceX’s advanced traceability platform is designed to simplify this process and empower businesses with the tools they need to succeed.

TraceX’s Food Traceability Platform reduces these burdens by offering a scalable, cloud-based solution that automates traceability processes. The platform digitizes data collection, saving operational costs. Businesses can choose features that align with their specific needs, avoiding unnecessary expenses. TraceX with its interoperable platform, ensures smooth communication between existing ERP, WMS, and supply chain management systems. API-driven architecture allows easy connectivity across platforms.

Multi-tier supply chains are complex, with numerous stakeholders involved at every step. Ensuring end-to-end visibility is a significant challenge. TraceX simplifies this by providing Immutable records ensure accurate data sharing across tiers. Businesses can monitor the journey of raw materials to finished products with live tracking.

Identify the origins of raw materials to meet sustainability requirements like the EU Deforestation Regulation (EUDR).

Traceability standards like ISO 22005, FSMA, and HACCP require accurate record-keeping and reporting. TraceX’s platform ensures compliance by automated data logging, customizable reporting tools and audit-ready features

Global traceability standards are more than just guidelines—they are essential tools for fostering transparency, trust, and sustainability across supply chains. By adhering to frameworks like GS1, ISO 22005, FSMA, and HACCP, businesses can enhance operational efficiency, ensure compliance with global regulations, and meet consumer demand for ethical and safe products. As supply chains become increasingly complex, leveraging technology such as blockchain, IoT, and AI can make the adoption of these standards seamless and impactful. The result? A supply chain that’s not only efficient but also trusted by stakeholders at every level.

Global traceability standards, such as GS1 and ISO 22005, provide frameworks for tracking products across supply chains. They are crucial for ensuring safety, quality, and sustainability while fostering trust among consumers and regulators.

Traceability standards help businesses reduce inefficiencies, comply with regulations, improve brand reputation, and enable data-driven decision-making. They also enhance consumer trust by ensuring transparency and ethical sourcing.

Technologies like blockchain ensure transparent and tamper-proof records, IoT provides real-time tracking, and AI delivers actionable insights for better decision-making. These tools simplify compliance and enhance supply chain visibility.