Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Learn how the FSMA (Food Safety Modernization Act) emphasizes traceability for food safety. Discover its requirements, challenges, and the role of technology in ensuring compliance.

Imagine a world where a single contaminated batch of food can be traced back to its source in seconds, preventing widespread health crises and saving lives. This is the promise of the Food Safety Modernization Act (FSMA), a game-changer in food safety regulations. However, many businesses are struggling to meet FSMA’s stringent traceability requirements.

With complex supply chains and outdated manual recordkeeping, ensuring compliance can feel like navigating a maze. For food producers, processors, and distributors, the stakes are high—non-compliance could mean hefty fines, damaged reputations, and, most importantly, compromised consumer safety. Let’s explore how FSMA redefines food traceability and why businesses must embrace modern solutions to stay ahead.

Key Takeaways

The Food Safety Modernization Act (FSMA) is one of the most significant food safety laws introduced in the United States. It was signed into law in 2011 with a clear mission: to make food safer for everyone.

For years, food safety practices were mostly reactive. Issues were addressed only after outbreaks or contamination events occurred. FSMA flips this approach on its head. Instead of waiting for a problem to arise, it emphasizes prevention—identifying potential risks in food production and supply chains before they can cause harm.

At its core, FSMA aims to:

One of the standout features of FSMA is the Food Traceability Rule. This rule requires food businesses to create detailed records of their products’ journey through the supply chain—from farms to processing plants to retailers. The goal is simple but crucial: if a contamination issue arises, authorities can pinpoint its source immediately and remove the affected products from the market.

By shifting to a preventive approach and setting stricter regulatory mandates, FSMA ensures that businesses prioritize food safety every step of the way. It’s not just about compliance; it’s about fostering consumer trust and building a more transparent food system.

When it comes to food safety, traceability plays a starring role. But what exactly does traceability mean, and why is it so important for FSMA compliance?

Simply put, traceability is the ability to track a food product’s journey through the supply chain—starting from its origin (like a farm or fishing boat) to its final destination on the store shelf or your plate. It’s like giving every product a passport, documenting every step it takes along the way.

Imagine a foodborne illness outbreak linked to a contaminated batch of spinach. Without proper traceability, identifying the source of the problem could take weeks, putting more consumers at risk and damaging trust in the food industry. Traceability ensures that affected products can be quickly identified and removed, protecting both public health and brand reputation.

Under the Food Safety Modernization Act (FSMA), traceability isn’t just a good idea—it’s a requirement. Let’s break down what FSMA expects from food businesses:

FSMA mandates that food companies maintain detailed records of every step in their supply chain. This means documenting:

These records ensure that every product is traceable backward (to its source) and forward (to its next destination).

Under FSMA’s Food Traceability Rule, businesses must focus on specific points in the supply chain called Critical Tracking Events (CTEs). These are moments when food is transformed, packaged, or transported—key points where something could go wrong.

For each CTE, businesses must capture Key Data Elements (KDEs), such as:

This combination of CTEs and KDEs provides a complete picture of the product’s journey, ensuring transparency and accountability.

In the event of an audit, inspection, or recall, businesses must provide traceability data at a moment’s notice. This means no scrambling through paper records or outdated systems. Real-time access to digital records is becoming the gold standard for FSMA compliance.

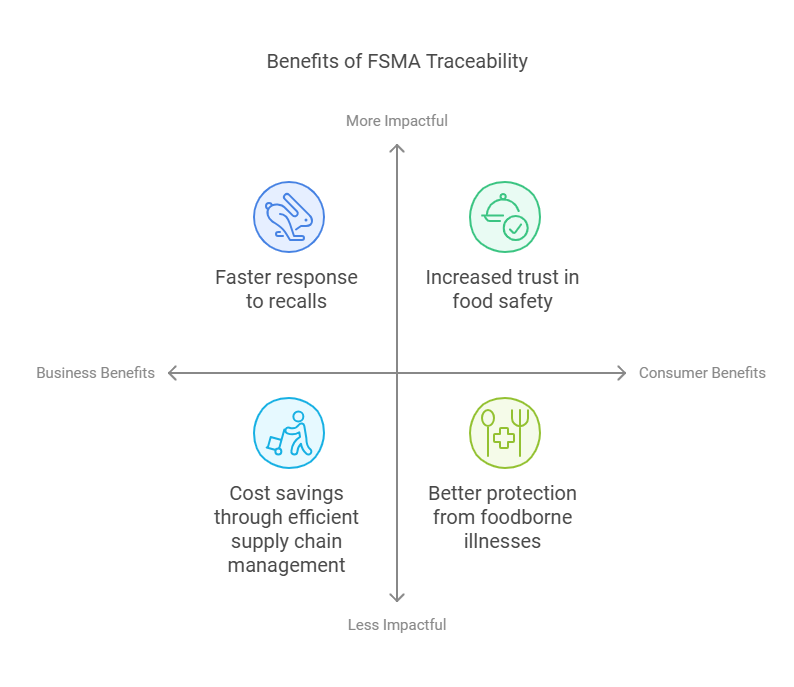

Traceability isn’t just about following the rules—it’s about building a safer, more trustworthy food system. For businesses, it means fewer risks, faster responses to problems, and greater confidence from consumers who know exactly where their food comes from. As FSMA makes clear, traceability is the backbone of food safety, and every business has a role to play in strengthening it.

Complying with the FSMA traceability standards is no small feat. While the regulations aim to make food safer for everyone, many businesses encounter significant challenges along the way.

Many businesses still rely on paper-based systems to track their supply chains. While this might have worked in the past, it’s far from ideal today. Paper records are:

With FSMA requiring detailed, accurate, and easily accessible records, manual processes just can’t keep up. Businesses need faster, more reliable ways to document and retrieve traceability data.

Today’s food supply chains are anything but straightforward. Products pass through multiple hands—farmers, processors, distributors, retailers—before they reach consumers. Each stage adds another layer of complexity.

For example, let’s say you’re sourcing ingredients from multiple suppliers across different regions. How do you ensure that every batch is tracked correctly from start to finish? And what happens if one supplier isn’t maintaining proper records?

The more complex the supply chain, the harder it is to maintain transparency and meet FSMA standards. Gaps in communication or recordkeeping at any point can jeopardize compliance and food safety.

For smaller producers and distributors, FSMA compliance can feel overwhelming. They often face:

While larger companies may have the resources to adapt quickly, smaller players often struggle to keep up, risking non-compliance and potential penalties.

The challenges of meeting FSMA traceability standards highlight the need for modern, scalable solutions. Digital tools and technology, like traceability platforms, can help streamline recordkeeping, simplify supplier tracking, and make compliance more accessible for businesses of all sizes. Addressing these challenges isn’t just about avoiding penalties—it’s about building a safer, more efficient food system for everyone.

When it comes to complying with FSMA traceability standards, technology is proving to be a game-changer. From streamlining operations to improving supply chain transparency, digital solutions are helping businesses navigate the complexities of compliance with ease.

Gone are the days of paper records and manual tracking. Digital traceability platforms provide a modern, efficient way to monitor and manage every stage of the supply chain. Let’s explore how specific technologies play a role:

By integrating these technologies into their operations, businesses can unlock a host of benefits that make FSMA compliance much easier:

Navigating the complexities of FSMA compliance can be challenging, but TraceX is here to make it simpler and more efficient. With our cutting-edge digital traceability platform, businesses can seamlessly align with FSMA’s stringent requirements while improving supply chain transparency and operational efficiency.

TraceX offers an end-to-end traceability platform designed specifically to help food businesses meet FSMA traceability standards. Our solution ensures that every critical tracking event (CTE) and key data element (KDE) is captured, stored, and easily accessible, providing you with the tools you need for audit readiness and consumer trust.

The FSMA has redefined the way we approach food safety, placing traceability at the core of compliance. By adopting advanced traceability technologies and streamlining supply chain operations, businesses can not only meet regulatory requirements but also build consumer trust and brand loyalty. The road to FSMA compliance may seem complex, but with the right tools and commitment, it becomes an opportunity to create a safer, more transparent food ecosystem.

FSMA is the Food Safety Modernization Act, a regulation aimed at preventing foodborne illnesses through improved safety measures. Traceability ensures quick identification of contaminated products, minimizing health risks and product recalls.

CTEs are events such as harvesting, processing, and shipping that must be tracked, while KDEs are the specific data points recorded at each stage. Together, they ensure end-to-end visibility in the food supply chain.

Technologies like blockchain, IoT, and digital traceability platforms automate recordkeeping, enable real-time tracking, and provide transparency across the supply chain, simplifying compliance and enhancing food safety.